Bottling it

Selling bottled water to a nation with the quality and quantity of town supply water like New Zealand’s may have once seemed akin to selling ice to Eskimos, but in the past 10 years Kiwis have been taking to sipper bottles with enthusiasm.

The switch in mentality was helped along by Auckland’s drought of 1994, and in 2002 a pipeline was built to supplement the municipal supply with water from the polluted Waikato River. Despite filtering and thorough treatment, many Aucklanders were revolted by the idea, and began investing in water filtration systems, boiling water, chilling it in the fridge, and buying bottled water. In the health wave of the past decade, the rest of the country followed suit, responding to marketing campaigns promising a guilt-free beverage without sugar, artificial additives, caffeine or alcohol, packaged in an attractive and convenient recyclable sipper bottle.

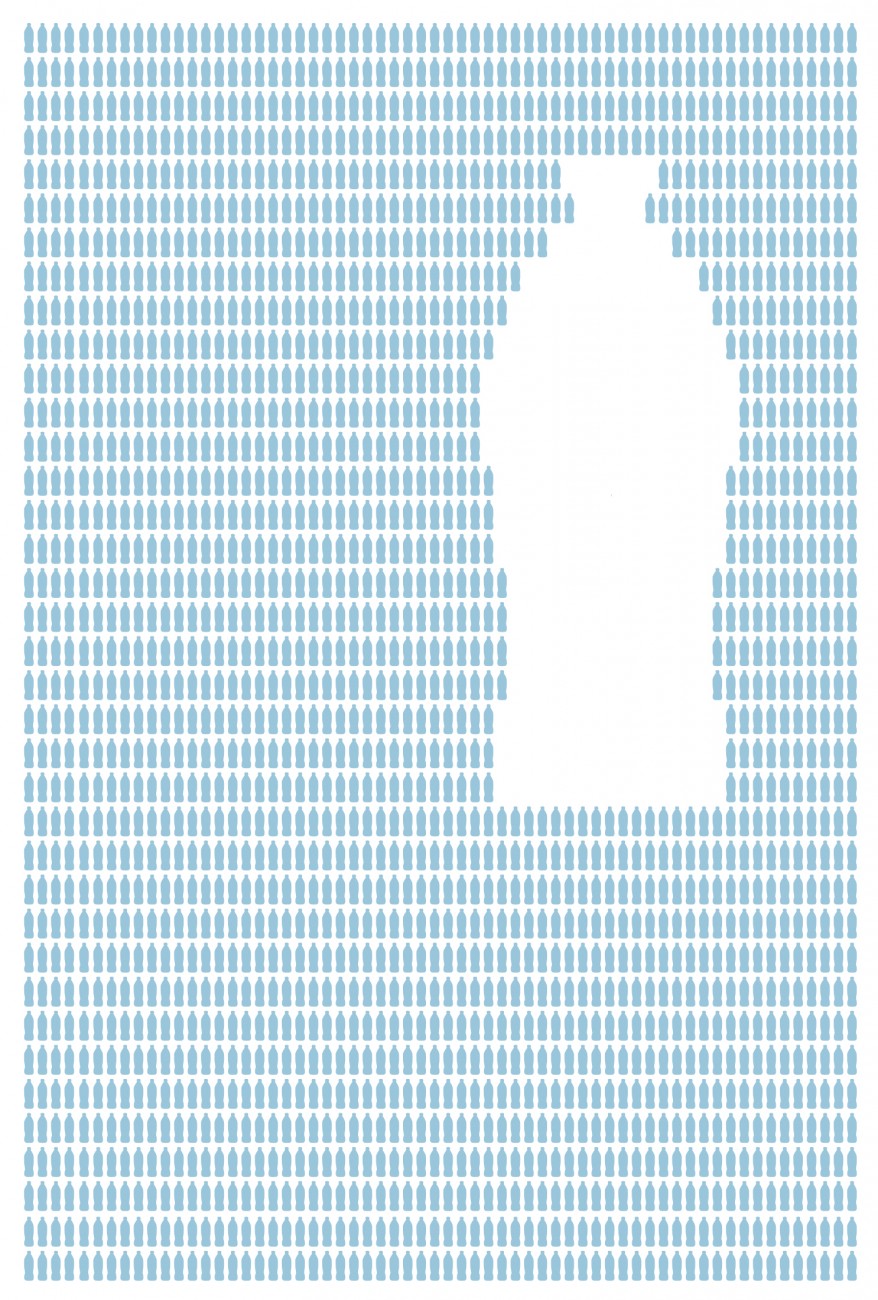

But it comes at a cost. The manufacturing process consumes between two and five litres of water, depending on the facility, and 42.5 ml of oil for every one-litre plastic sipper bottle. Coca-Cola’s Putaruru bottling plant can produce 50,000 bottles of water daily, representing more than 13 barrels of crude oil.

Incidentally, the Putaruru town supply in South Waikato is the source of around 60 per cent of New Zealand bottled water including Blue Spring, Pump and Cool Blue, which are sold for more than 2000 times the price of water from a Putaruru tap.